February 18, 2022

Mass Timber Joinery Design for Digital Fabrication and De-constructability

ARC Fellow: Nathan Brown

Degree Program: M Arch; MS Arch, Design Technology

Faculty Advisors: Tomás Méndez Echenagucia, Architecture

Firm: Turner Construction

Firm Advisors: Josh Lohr

Project dates: Autumn 2021 – Autumn 2022

Read the Project Thesis

View Presentation Slides

Watch the Presentation

More about the project:

When looking at building construction, a significant portion of building waste is produced by making buildings that will be torn down in 20-50 years. This is partly due to the difficulty of disassembly, where each part of assembly is attached with adhesives or permanent mechanical fasteners. Recycling products also brings about difficulty when systems use a multitude of materials for their purposes. In addition, most materials that are used in the construction industry contribute heavily to carbon emissions. Timber products provide the benefit of being malleable and having the ability to store carbon. We can address both the issues of carbon emissions and building waste at the same time by constructing a timber structural system that utilizes integral mechanical attachments rather than fasteners.

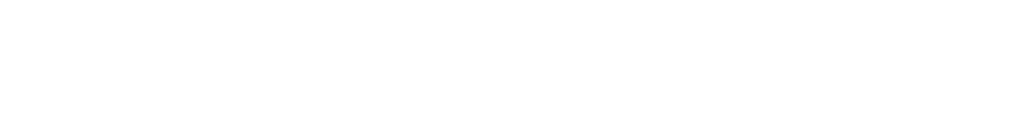

An assembled version of the Yakushiji Picture hall using a variety of digital fabrication techniques. NATHAN BROWN, JOSH LOHR, AND TURNER

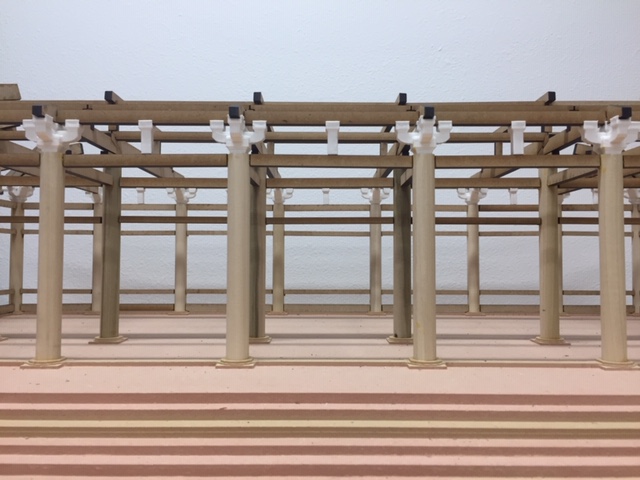

Layout for a 3-axis CNC machine in order to fabricate a gooseneck joint. NATHAN BROWN, JOSH LOHR, AND TURNER

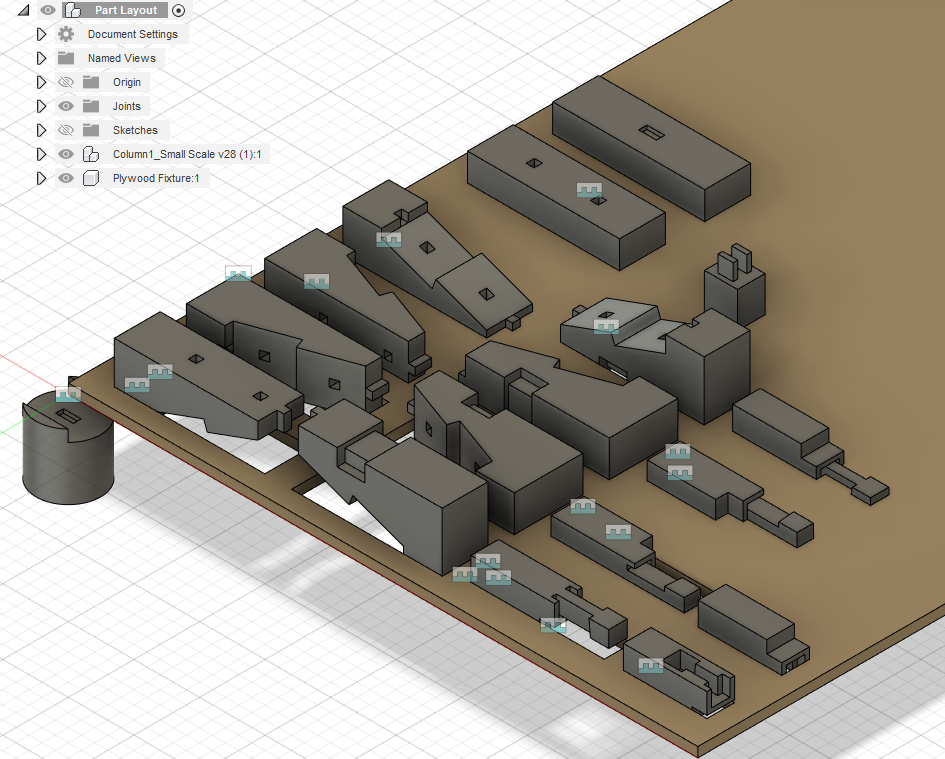

Voxel based joint that can be customized and recreated using digital fabrication techniques. MARIA LARSSON, HIRONORI YOSHIDA, NOBUYUKI UMETANI, AND TAKEO IGARASHI